In the burgeoning cannabis industry of California, ensuring the safety and quality of cannabis products is paramount. Cannabis growers and manufacturers spend countless hours producing consumer products that are safe and high quality. The last thing you want as a grower or manufacturer is for your product to fail DCC Testing Controls. With the growing industry, consumers increasingly seek reliable and trustworthy products and certified cannabis testing labs play a pivotal role in upholding these standards for the industry.

Certified Los Angeles cannabis testing services and labs adhere to the stringent testing regulations set forth by the California Department of Cannabis Control (DCC) to protect growers, manufacturers, and consumers. Testing labs are a key component of the vitality and trust of the industry. In this comprehensive guide, we delve into the California DCC testing controls and what occurs when a cannabis product fails a test.

Table of Contents

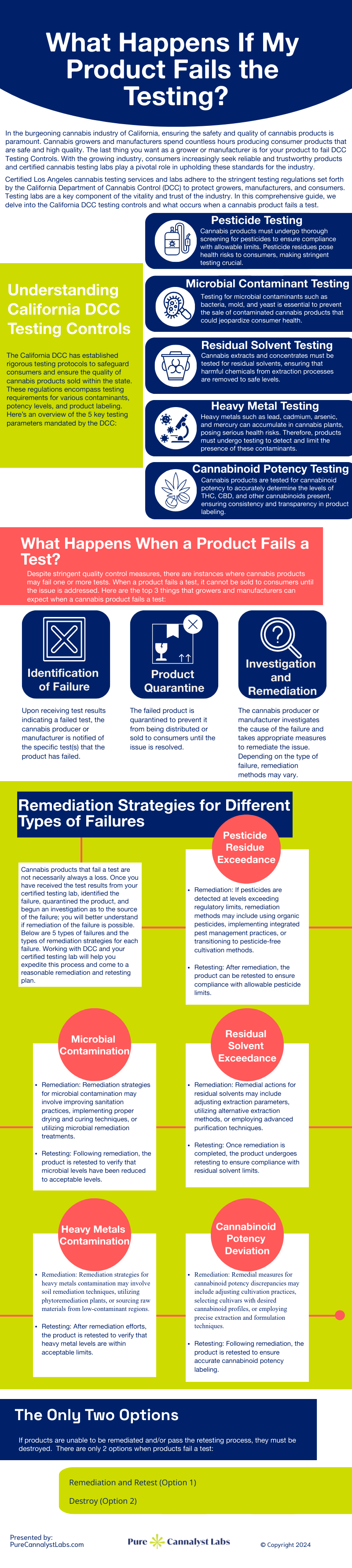

ToggleUnderstanding California DCC Testing Controls

The California DCC has established rigorous testing protocols to safeguard consumers and ensure the quality of cannabis products sold within the state. These regulations encompass testing requirements for various contaminants, potency levels, and product labeling. Here’s an overview of the 5 key testing parameters mandated by the DCC:

– Pesticide Testing: Cannabis products must undergo thorough screening for pesticides to ensure compliance with allowable limits. Pesticide residues pose health risks to consumers, making stringent testing crucial.

– Microbial Contaminant Testing: Testing for microbial contaminants such as bacteria, mold, and yeast is essential to prevent the sale of contaminated cannabis products that could jeopardize consumer health.

– Residual Solvent Testing: Cannabis extracts and concentrates must be tested for residual solvents, ensuring that harmful chemicals from extraction processes are removed to safe levels.

– Heavy Metal Testing: Heavy metals such as lead, cadmium, arsenic, and mercury can accumulate in cannabis plants, posing serious health risks. Therefore, products must undergo testing to detect and limit the presence of these contaminants.

– Cannabinoid Potency Testing: Cannabis products are tested for cannabinoid potency to accurately determine the levels of THC, CBD, and other cannabinoids present, ensuring consistency and transparency in product labeling.

What Happens When a Product Fails a Test?

Despite stringent quality control measures, there are instances where cannabis products may fail one or more tests. When a product fails a test, it cannot be sold to consumers until the issue is addressed. Here are the top 3 things that growers and manufacturers can expect when a cannabis product fails a test:

– Identification of Failure: Upon receiving test results indicating a failed test, the cannabis producer or manufacturer is notified of the specific test(s) that the product has failed.

– Product Quarantine: The failed product is quarantined to prevent it from being distributed or sold to consumers until the issue is resolved.

– Investigation and Remediation: The cannabis producer or manufacturer investigates the cause of the failure and takes appropriate measures to remediate the issue. Depending on the type of failure, remediation methods may vary.

Remediation Strategies for Different Types of Failures

Cannabis products that fail a test are not necessarily always a loss. Once you have received the test results from your certified testing lab, identified the failure, quarantined the product, and begun an investigation as to the source of the failure; you will better understand if remediation of the failure is possible. Below are 5 types of failures and the types of remediation strategies for each failure. Working with DCC and your certified testing lab will help you expedite this process and come to a reasonable remediation and retesting plan.

-

Pesticide Residue Exceedance:

- Remediation: If pesticides are detected at levels exceeding regulatory limits, remediation methods may include using organic pesticides, implementing integrated pest management practices, or transitioning to pesticide-free cultivation methods.

- Retesting: After remediation, the product can be retested to ensure compliance with allowable pesticide limits.

-

Microbial Contamination:

- Remediation: Remediation strategies for microbial contamination may involve improving sanitation practices, implementing proper drying and curing techniques, or utilizing microbial remediation treatments.

- Retesting: Following remediation, the product is retested to verify that microbial levels have been reduced to acceptable levels.

-

Residual Solvent Exceedance:

- Remediation: Remedial actions for residual solvents may include adjusting extraction parameters, utilizing alternative extraction methods, or employing advanced purification techniques.

- Retesting: Once remediation is completed, the product undergoes retesting to ensure compliance with residual solvent limits.

-

Heavy Metals Contamination:

- Remediation: Remediation strategies for heavy metals contamination may involve soil remediation techniques, utilizing phytoremediation plants, or sourcing raw materials from low-contaminant regions.

- Retesting: After remediation efforts, the product is retested to verify that heavy metal levels are within acceptable limits.

-

Cannabinoid Potency Deviation:

- Remediation: Remedial measures for cannabinoid potency discrepancies may include adjusting cultivation practices, selecting cultivars with desired cannabinoid profiles, or employing precise extraction and formulation techniques.

- Retesting: Following remediation, the product is retested to ensure accurate cannabinoid potency labeling.

The Only Two Options

If products are unable to be remediated and/or pass the retesting process, they must be destroyed. There are only 2 options when products fail a test:

– Remediation and Retest (Option 1)

– Destroy (Option 2)

In the highly regulated cannabis industry of California, adherence to testing controls mandated by the California DCC is essential to ensure consumer safety and product quality. At Pure Cannalyst Labs, we are committed to upholding these standards and assisting cannabis producers and manufacturers in navigating the complexities of testing and compliance. By understanding the testing parameters, identifying failures, and implementing appropriate remediation and retesting strategies, the cannabis industry can continue to provide safe, reliable, and compliant products to consumers across California.

Infographic