As a licensed cannabis distributor or micro-business (cultivation, manufacturing, or retail), your goal is to provide consumers with the highest quality and safe cannabis products on the market. However, ensuring that your Los Angeles cannabis testing lab completes cannabis sampling in compliance as outlined by the California Department of Cannabis Control (DCC) can be overwhelming. The current DCC Commercial Cannabis Regulations include 239 pages of guidance that must be followed. In this article, we will explore Chapter 6, Article 3 of the DCC regulations and provide a guide to understanding compliance cannabis sampling in California.

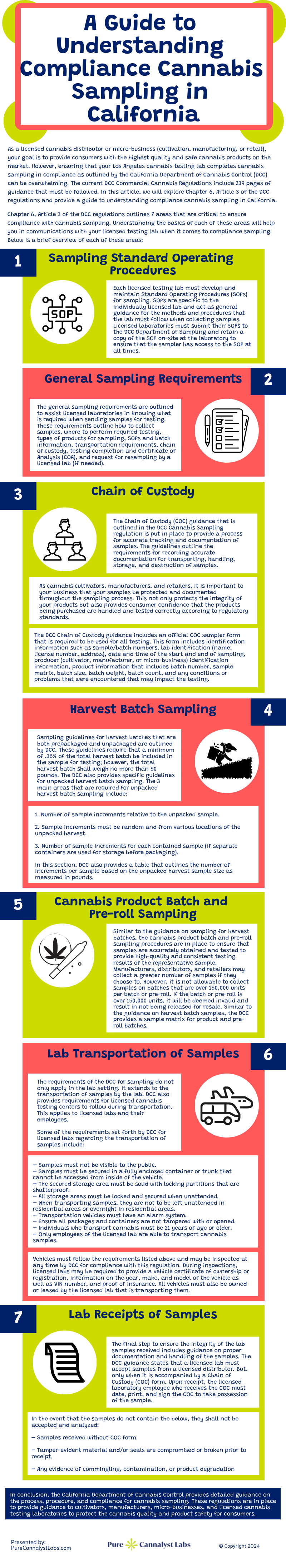

Chapter 6, Article 3 of the DCC regulations outlines 7 areas that are critical to ensure compliance with cannabis sampling. Understanding the basics of each of these areas will help you in communications with your licensed testing lab when it comes to compliance sampling. Below is a brief overview of each of these areas:

Table of Contents

Toggle1. Sampling Standard Operating Procedures

Each licensed testing lab must develop and maintain Standard Operating Procedures (SOPs) for sampling. SOPs are specific to the individually licensed lab and act as general guidance for the methods and procedures that the lab must follow when collecting samples. Licensed laboratories must submit their SOPs to the DCC Department of Sampling and retain a copy of the SOP on-site at the laboratory to ensure that the sampler has access to the SOP at all times.

2. General Sampling Requirements

The general sampling requirements are outlined to assist licensed laboratories in knowing what is required when sending samples for testing. These requirements outline how to collect samples, where to perform required testing, types of products for sampling, SOPs and batch information, transportation requirements, chain of custody, testing completion and Certificate of Analysis (COA), and request for resampling by a licensed lab (if needed).

3. Chain of Custody

The Chain of Custody (COC) guidance that is outlined in the DCC Cannabis Sampling regulation is put in place to provide a process for accurate tracking and documentation of samples. The guidelines outline the requirements for recording accurate documentation for transporting, handling, storage, and destruction of samples.

As cannabis cultivators, manufacturers, and retailers, it is important to your business that your samples be protected and documented throughout the sampling process. This not only protects the integrity of your products but also provides consumer confidence that the products being purchased are handled and tested correctly according to regulatory standards.

The DCC Chain of Custody guidance includes an official COC sampler form that is required to be used for all testing. This form includes identification information such as sample/batch numbers, lab identification (name, license number, address), date and time of the start and end of sampling, producer (cultivator, manufacturer, or micro-business) identification information, product information that includes batch number, sample matrix, batch size, batch weight, batch count, and any conditions or problems that were encountered that may impact the testing.

4. Harvest Batch Sampling

Sampling guidelines for harvest batches that are both prepackaged and unpackaged are outlined by DCC. These guidelines require that a minimum of .35% of the total harvest batch be included in the sample for testing; however, the total harvest batch shall weigh no more than 50 pounds. The DCC also provides specific guidelines for unpacked harvest batch sampling. The 3 main areas that are required for unpacked harvest batch sampling include:

1. Number of sample increments relative to the unpacked sample.

2. Sample increments must be random and from various locations of the unpacked harvest.

3. Number of sample increments for each contained sample (if separate containers are used for storage before packaging).

In this section, DCC also provides a table that outlines the number of increments per sample based on the unpacked harvest sample size as measured in pounds.

5. Cannabis Product Batch and Pre-roll Sampling

Similar to the guidance on sampling for harvest batches, the cannabis product batch and pre-roll sampling procedures are in place to ensure that samples are accurately obtained and tested to provide high-quality and consistent testing results of the representative sample. Manufacturers, distributors, and retailers may collect a greater number of samples if they choose to. However, it is not allowable to collect samples on batches that are over 150,000 units per batch or pre-roll. If the batch or pre-roll is over 150,000 units, it will be deemed invalid and result in not being released for resale. Similar to the guidance on harvest batch samples, the DCC provides a sample matrix for product and pre-roll batches.

6. Lab Transportation of Samples

The requirements of the DCC for sampling do not only apply in the lab setting. It extends to the transportation of samples by the lab. DCC also provides requirements for licensed cannabis testing centers to follow during transportation. This applies to licensed labs and their employees.

Some of the requirements set forth by DCC for licensed labs regarding the transportation of samples include:

– Samples must not be visible to the public.

– Samples must be secured in a fully enclosed container or trunk that cannot be accessed from inside of the vehicle.

– The secured storage area must be solid with locking partitions that are shatterproof.

– All storage areas must be locked and secured when unattended.

– When transporting samples, they are not to be left unattended in residential areas or overnight in residential areas.

– Transportation vehicles must have an alarm system.

– Ensure all packages and containers are not tampered with or opened.

– Individuals who transport cannabis must be 21 years of age or older.

– Only employees of the licensed lab are able to transport cannabis samples.

Vehicles must follow the requirements listed above and may be inspected at any time by DCC for compliance with this regulation. During inspections, licensed labs may be required to provide a vehicle certificate of ownership or registration, information on the year, make, and model of the vehicle as well as VIN number, and proof of insurance. All vehicles must also be owned or leased by the licensed lab that is transporting them.

7. Lab Receipts of Samples

The final step to ensure the integrity of the lab samples received includes guidance on proper documentation and handling of the samples. The DCC guidance states that a licensed lab must accept samples from a licensed distributor. But, only when it is accompanied by a Chain of Custody (COC) form. Upon receipt, the licensed laboratory employee who receives the COC must date, print, and sign the COC to take possession of the sample.

In the event that the samples do not contain the below, they shall not be accepted and analyzed:

– Samples received without COC form.

– Tamper-evident material and/or seals are compromised or broken prior to receipt.

– Any evidence of commingling, contamination, or product degradation

In conclusion, the California Department of Cannabis Control provides detailed guidance on the process, procedure, and compliance for cannabis sampling. These regulations are in place to provide guidance to cultivators, manufacturers, micro-businesses, and licensed cannabis testing laboratories to protect the cannabis quality and product safety for consumers.

Infographic